|

MICROCON® 800

- Survivor Series

The purpose of the MICROCON® SS is to provide

a rapid, simple and economical means of providing high

volume highly filtered and irradiated safe breathable

air to a secured contained space. The shelter will maintain

a slight positive pressure by the air being admitted.

It's portable and can be wheeled to a predetermined location

or permanently mounted and installed. The two pre-requisites

for installation are an air source and 115V power.

Outside air (or any

air source) is drawn into the unit through a 10-12" duct

that attaches to the duct collar mounted to the intake

of the HEPA filter cube. After numerous stages of filtration

any incoming air has been thoroughly cleansed, irradiated

and rendered safe of any airborne pollutants or contaminants.

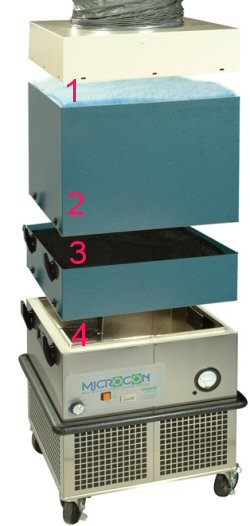

1st Stage

- particulate pre-filtration:

Incoming

air is first filtered through a 100% polyester

fiber, 3-stage panel filter. The polyester filter

will not absorb moisture or shed. The composition

of the matrix is a dry open web that serves a first

stage pre-filter for entrapment of larger size

particles. The second stage is comprised of finer

denier fibers to entrap smaller particles. The

final layer is a tightly needled matrix treated

with a non migrating tackifier for even smaller

size particles. The progressive filtration feature

of graduated densities allows for the finer size

particulate to become entrapped deep within the

filter thereby increasing filter life and efficiency.

This first stage filter is to provide the larger

size particles from reaching the HEPA filter thereby

increasing its life and efficiency. Incoming

air is first filtered through a 100% polyester

fiber, 3-stage panel filter. The polyester filter

will not absorb moisture or shed. The composition

of the matrix is a dry open web that serves a first

stage pre-filter for entrapment of larger size

particles. The second stage is comprised of finer

denier fibers to entrap smaller particles. The

final layer is a tightly needled matrix treated

with a non migrating tackifier for even smaller

size particles. The progressive filtration feature

of graduated densities allows for the finer size

particulate to become entrapped deep within the

filter thereby increasing filter life and efficiency.

This first stage filter is to provide the larger

size particles from reaching the HEPA filter thereby

increasing its life and efficiency.

2nd Stage

- high efficiency particulate filtration:

The high capacity HEPA filter is manufactured

with a high alpha high capacity micro-glass media. Filters

are 99.99% efficient and tested individually and certified

to have a maximum efficiency of not less than 99.97%

when challenged with .3 micron size particles of a thermally

generated challenge agent. The HEPA filter is permanently

sealed and encapsulated within a steel enclosure that

guarantees a self-aligning leak free seal. HEPA filters

are the only filtration device that has the capacity

to contain nuclear particles. True bag-out filter replacement

eliminates any exposure to the contaminated filter by

maintenance personnel during filter renewal procedures.

3rd Stage

- odor/fume adsorption:

Once the particulate matter is eliminated from

the air stream by the progressive filtration stages,

the gas air pollutants are then addressed by a series

of activated carbon cells. These contain 60% activated

premium grade coconut shell carbon granules for absorption

of odors and gases from the air-stream. There is also

the addition of impregnated carbons and potassium permanganate

for removal of compounds such as ammonia, hydrogen sulfide

and formaldehyde which carbon has little effect on.

4th Stage

- germicidal irradiation : :

The base of the fan module contains four 16",

254nm germicidal ultraviolet (ultra violet)

lamps. The 254nm wavelength had been recognized as

an effective means

of air disinfection. The UV works by breaking down

and altering the DNA molecules which consequently destroys

replication and kills the cell. Where HEPA filters

have

proven to be effective in containment of microbial

contamination such as bacteria, mold spores, mildew,

dust particles

and pollen, UV works on smaller size organisms that

would not be contained by the HEPA filter. These would

include

organisms in the various virus families. The lamps

are purposely positioned downstream of the HEPA filters

to

protect the lamps surfaces. Since all particulate matter

has been eliminated by the air stream there are no

airborne particles to attach themselves to the lamp

surface thereby

reducing their irradiation levels. It also eliminates

the need for periodic cleaning of the lamp surfaces

which is a customary and required procedure when utilizing

UV lamps. Lamps are designed for approximately 6000

hrs.

of operation before they require renewal.

The unit is modular in design and each stage is an individual cell that locks

and seals to the proceeding module. The

base is designed to exhaust air in a 360° direction.

This disperses air in all directions and eliminates positioning concerns.

In the event a single exhaust duct is required, we simply use block-out

panels to block exhaust in all but one direction. This could be of any

of the four sides. locks

and seals to the proceeding module. The

base is designed to exhaust air in a 360° direction.

This disperses air in all directions and eliminates positioning concerns.

In the event a single exhaust duct is required, we simply use block-out

panels to block exhaust in all but one direction. This could be of any

of the four sides.

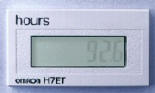

A

variable speed electronic fan control knob adjusts the

cfm volume. An electronic hour meter monitors the overall

operation time of the system. A pressure differential

gauge is incorporated to constantly monitor the pressure

differential in the system thereby identifying when

filters require replacement. the

cfm volume. An electronic hour meter monitors the overall

operation time of the system. A pressure differential

gauge is incorporated to constantly monitor the pressure

differential in the system thereby identifying when

filters require replacement.

The

fan is permanently sealed and self lubricated and requires

no maintenance or adjustment.

The

base is of stainless steel construction with four,

four inch rubber wheels (two locking). The exterior

surfaces of the filters are powder coated baked on

steel.

If

permanent installation is required, a pedestal can

be included to fasten to the floor, preventing mobility. If

permanent installation is required, a pedestal can

be included to fasten to the floor, preventing mobility.

Sizing:

Adequate air flow in a shelter calculates to about

4 cubic feet per minute (cfm) per person (or 6.6 meters

cubed per hour (m3/h)). In a humid environment these

figures should be increased by a factor of 2. Based upon

a conservative air delivery of 600 cfm, there is 36,000

cfm of filtered air being delivered each hour.

The integrity of

the shelter itself is critical to survival success.

An air tight shelter is paramount with a slight positive

pressurization to the surrounding areas. An exhaust

system is required to rid the shelter of pollutants

and gases generated within the space.

Other system considerations:

The MICROCON® is the only component in a system that

must include various other components and systems to

accomplish a total secure environment. For example, a

power source must be available to provide power and run

the various appliances needed. This might include a gas

powered generator and supply of fuel. Food type and storage

must be addressed. Communication equipment to allow contact

and information with the outside. Some means to condition

(heat or cooling) the inside air. Heat and humidity will

increase very rapidly inside a sealed shelter area. A

means for the elimination of waste material. A system

for storage and replenishment for the water supply, and

light sources, both battery and generator types.

The design of the

shelter should depend upon the anticipated longevity

of occupation, the number of occupants, and to what

degree of inclusion the systems must be incorporated.

Several factors will ultimately determine the success

rate of the shelter such as the severity of an incident,

weather conditions, and proximity to ground zero. Being

prepared will only improve the survival rate for those

who plan ahead.

|