Meets all CDC

Guidelines

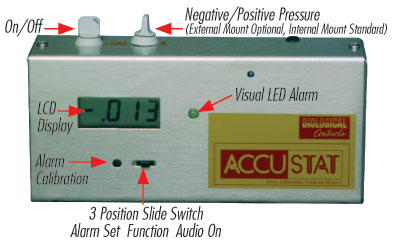

• Accurate to .001” W.G.

• Status LED

• Large scale display

• Keyed On/Off

• User alarm set point

• Audible alarm with mute

• One minute delay

• 4/20 MA output available

• Monitor negative or positive

|

ACCUSTAT™ Stationary Model ACCUSTAT™ Stationary Model

The ACCUSTAT™ room pressure monitor is designed specifically for monitoring low negative or positive pressure differentials. Accurate pressurization is a vital step in creating a compliant, controlled and safe environment. Ideally suited for monitoring hospital isolation rooms or pressure differentials in other critical applications.

State-of-the-art microprocessor design operates from a single positive supply power source. Temperature compensation provides for consistent predictable performance within specified temperature ranges. Pressure readings are instantaneous and accurate with many optional features to allow for custom designed installations State-of-the-art microprocessor design operates from a single positive supply power source. Temperature compensation provides for consistent predictable performance within specified temperature ranges. Pressure readings are instantaneous and accurate with many optional features to allow for custom designed installations

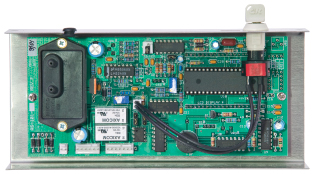

State-of-the-Art Solid-State Circuitry

|

| View of internal printed circuit board. |

A large lighted digital display readout identifies instantaneous sub-fractional pressure changes when compared to the adjoining areas. Pressure readings are accurate to within .001” WG with audio and visual alarms identifying unsatisfactory conditions. The ACCUSTAT™ utilizes a highly sensitive pressure transducer eliminating the varying inconsistencies of “airflow” monitors. Air pressure tends to be more consistent and less corrupted by airflow direction disruption, thereby reducing the frequency of false alarms and inconsistent readings.

The need for monitoring pressure differentials between areas has a broad range of applications throughout many critical environments. From the concerns and safety of health care personnel to the protection of processes, products and equipment, maintaining a positive or a negative pressurization environment satisfies industry compliance. ACCUSTAT™ pressure monitoring capabilities include:

For Negative

Pressure

Autopsy Room, Body Holding Room, Laboratory, Isolation Rooms, Decontamination Areas, Linen Sorting, ETO Sterilizer Room, Soiled Utility Rooms, X-Ray.

For Positive Pressure

Clean linen storage, Clean workroom and holding areas, Delivery ICU, Med Rooms, Pharmacy, OR, Nursery, Recovery, Trauma.

Some of these areas need continual monitoring, while others need periodic monitoring. CDC Guidelines for TB Control of 1994 recommend, and OSHA enforces that “TB isolation rooms should be checked daily for negative pressure while being used for TB isolation”. Three different ACCUSTAT™ versions are designed for these varying needs.

|

|

Applications

• Hospital Room

Isolation

• Bone Marrow Suites

• Medical Labs

• Intensive Care Units

• Clean Rooms

• Emergency Rooms

• HVAC Systems

• Laundry Areas

• Research Facilities

• Hospital Labs

• Pharmaceutical Manufacturing

• Laboratory Pressurization

• Schools and Universities

• Construction & Renovation

|

ACCUSTAT™ P-2

Portable ACCUSTAT™ P-2

Portable

Same reliable accuracy, but built to go places

Biological Controls introduces its next generation ACCUSTAT P2 portable differential pressure monitor. For over 12 years the original ACCUSTAT P1 has provided reliable service, versatility and convenience as the original portable pressure monitoring device. The P2 has evolved with state-of -the-art instrumentation and lots of new features. Virtually all of it's components have been redesigned, re-engineered and upgraded. Monitor either positive or negative pressure by the flick of the switch. Measure pressures from .001" WG (inches of water) or display in Pascals. The ACCUSTAT P2 is a true pressure transducer and not an airflow meter. You get true direct accurate pressure readings regardless of the air quality and without recalibration or inconsistencies within the measured space.

The original P1 stainless steel case was tough, but the new P2 case is virtually indestructible and comes with its own unconditional lifetime warranty. New electronic state-of-art components are housed in this all new weatherproof compact polycarbonate case. We’re still lightweight at less than 5 lbs. but more durable, compact and totally self-contained in its lockable enclosure. The new P2 case has been designed to accommodate all of its accessories so they stow neatly, safely and conveniently inside the case. No loose accessories to get lost or damaged. Makes traveling with the unit, especially on a plane far easier and more convenient.  Being portable, extended battery life for the P2 was a major objective. So a new NiMH (Nickel-Metal Hydride) battery design was incorporated more than tripling the original battery life to over 48 hrs. on a single charge. A new battery status monitoring display provides up to the second remaining power usage. Unit can also operate on plug-in 100VAC-240VAC 50/60Hz power input. (international plug adapters are included) Automobile power port option is available for on-the-road charging using a car cigarette lighter port. New temperature compensation micro-circuits help improve reading stability between field use operations. Simple dial “zero” calibration feature makes occasional adjustment easy yet precise. All the data you need to know is easy to view and access and is directly at your fingertips. User friendly display panel with operational instructions permanently mounted makes set-up, operation and pressure monitoring easy, accurate and consistent. A large LCD display and LED indicators allow the user to adjust custom alert set points (both audible and visual.) The new P2 provides you instantaneous readings, unparalleled accuracy with incredible ease of operation. Being portable, extended battery life for the P2 was a major objective. So a new NiMH (Nickel-Metal Hydride) battery design was incorporated more than tripling the original battery life to over 48 hrs. on a single charge. A new battery status monitoring display provides up to the second remaining power usage. Unit can also operate on plug-in 100VAC-240VAC 50/60Hz power input. (international plug adapters are included) Automobile power port option is available for on-the-road charging using a car cigarette lighter port. New temperature compensation micro-circuits help improve reading stability between field use operations. Simple dial “zero” calibration feature makes occasional adjustment easy yet precise. All the data you need to know is easy to view and access and is directly at your fingertips. User friendly display panel with operational instructions permanently mounted makes set-up, operation and pressure monitoring easy, accurate and consistent. A large LCD display and LED indicators allow the user to adjust custom alert set points (both audible and visual.) The new P2 provides you instantaneous readings, unparalleled accuracy with incredible ease of operation.

Expect the same level of reliability and accuracy as from the original P1, but expect a new experience in versatility and portability with the new P2. The next generation of portable pressure monitoring instrumentation has just arrived.

ACCUSTAT™ P2DL

Differential Pressure Monitor and Data LoggerFor Even More Detailed Information

For Monitoring Negative and Positive Pressure in Asbestos Abatement, Lead Paint Abatement, Mold Abatement, Asbestos Remediation, Lead Paint Remediation and Mold Remediation Projects. For Monitoring Negative and Positive Pressure in Asbestos Abatement, Lead Paint Abatement, Mold Abatement, Asbestos Remediation, Lead Paint Remediation and Mold Remediation Projects.

Biological Controls introduces its next generation ACCUSTAT™ P2DL portable differential pressure monitor and data logger. For over 12 years the original ACCUSTAT™ P1 has provided reliable service, versatility and convenience as the original portable pressure monitoring device. Now, the new P2 has evolved with state-of-the-art instrumentation and lots of new features, including the ability to record and save data. Virtually all of the components have been redesigned, re- engineered and upgraded. Monitor either positive or negative pressure by the flick of the switch. Measure pressures from .001" WG (inches of water) or display in Pascals.

Sampling rates from once-a-second to once-every-12 hours

The data logging feature allows for storage of over 32,000 pressure readings that are time-stamped in permanent non-volatile memory so the data is safe regardless of what happens to P2DL power or the time needed to retrieve the data. Sampling rates from once-a-second to once-every-12 hours may be selected thereby providing data records that may extend from 9 hours to over 2 years.

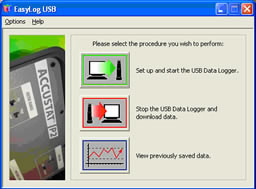

Windows® Compatible

The User Software provided on a CD (also downloadable from the WEB) is compatible with most Windows OS computers including laptops and presented with a simple icon-driven menu. This allows start-up, select units and sampling rates, query current status, stop, or reset the logging, as well as viewing the stored P2DL data in an auto-scaling X-Y graphical-format that can be named, printed or exported to Microsoft EXCEL for custom presentations.

Non-volatile Memory

Just plug the provided USB cable from the P2DL faceplate to your computer and start logging. The P2DL can continue to log or suspend logging without the computer interface once started. This allows readings to be gathered when it is not convenient to be connected to a computer. The data can then be retrieved at your convenience. Status indicators (LEDs) are provided on the P2DL to identify Logging-Active, Suspended-Logging, Memory Full, and System Diagnostic Verification.

Measures Actual Pressure

The ACCUSTAT™ P2DL is a true pressure transducer and not an airflow meter. You get true direct accurate pressure readings regardless of the air quality and without recalibration or inconsistencies within the measured space. Housed in a newly designed virtually indestructible lockable polycarbonate case, its weatherproof design can take all the rigors of the road. In fact, the case comeswith its own unconditional lifetime warranty. New electronic state-of-art components are housed within the lightweight (5 lb. all inclusive) compact totally self-contained enclosure. For added convenience the new P2DL has been designed to accommodate all of its accessories so they stow neatly, safely and conveniently inside the case. Nothing loose to get lost or damaged. Makes traveling with the unit, especially on a plane far easier and more convenient.

Battery operated or 100/240VAC plug in

Being portable, extended battery life for the P2DL was a major objective. So a new NiMH (Nickel-Metal Hydride) battery design was incorporated more than tripling the original battery life to over 48 hrs on a single charge. Meanwhile, a new battery status monitoring display provides up to the second remaining power usage. Unit can also operate on plug-in 100VAC-240VAC 50/60/Hz power input (international plug adapters are included). Automobile power port option is available for on-the-road charging using a car cigarette lighter port. New temperature compensation micro-circuits help improve reading stability between field use operations. Simple dial "zero" calibration feature makes occasional adjustment easy yet precise.

All the data you need to know is easy to view and access and is directly at your fingertips. User friendly

display panel with operational instructions permanently mounted makes set-up, operation and pressure monitoring easy, accurate and consistent. A large LCD display and LED indicators allow the user to adjust

custom alert set points (both audible and visual.) The new P2DL provides you instantaneous readings, unparallel accuracy with incredible ease of operation.

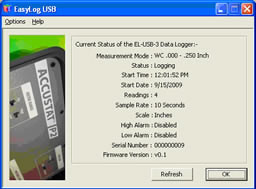

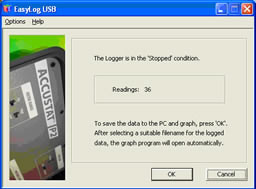

Screen Views: Easy Log, Icon Driven User Interface.

|

|

| Screen 1) Start data logger, stop, view saved data |

Screen 3) “Sample” screen showing current status of 11 function results |

|

|

| Screen 2) Select units of measurement, range and sampling rate |

Screen 4) “Sample” screen of final function |

|

|

Expect the same level of reliability and accuracy as from the original P1, but expect a new experience in

versatility and portability with the new P2DL. The next generation of portable pressure monitoring instrumentation has just arrived.

Faceplate Illustration

|

|

| |

Getting to know room pressure monitors for negative & positive pressure rooms. |

With various products available, deciding on the correct isolation room pressure monitoring equipment for your application is an important decision to make only once. As a result it will save you time, aggravation and money later. It can be easier to make that decision when all the important facts are addressed. It’s a decision you want to make once and not be reminded every time there is a staff complaint or malfunction.

Some companies claim to offer a “pressure room differential monitor” when in actuality it is instead an “air flow monitor.” An instrument where the probe head measures “flow direction” is an airflow monitor. They reference the flow rate and extrapolate from that a pressure reading. Flow rate to pressure reading, can something get lost in the translation? You bet, especially when the probe head gets clogged with the buildup of airborne particles constantly passing over it. That alters the flow rate in both directions. When the flow rate changes so do the calculations and the result is a false alarm, even if the room pressure is compliant, but the device doesn’t know that.

Periodic cleaning and adjustments are in order. Since many rooms can just barely maintain negativity the slightest variance in pressure even caused by negative pressure room users and maintenance personnel who have to contend with irrelevant alarms.

The ACCUSTAT Room Pressure Monitor by comparison is a true room pressure monitoring device. Airflow isn’t measured, only differential air pressure. The quality of the air is irrelevant because nothing passes through or over the probe, so nothing needs to be cleaned, adjusted or replaced. Particles of dust don’t influence our room pressure readings. Forgetting to clean the probe doesn’t produce false alarms. Blocking or a sudden stream of air across the probe head doesn’t alter the readings with the ACCUSTAT, because that shouldn’t alter the pressure.

The ACCUSTAT maintains accurate consistent readings and does not degradate with use. The ACCUSTAT’s consistent monitoring to .001” WG is compliant with current CDC guidelines for isolation room monitoring. The minute delay, keyed on/off, lighted numeric display, muting, remote, colored LED and many more features are part of the ACCUSTAT package. You can be guaranteed years of trouble-free operation. Thousands of ACCUSTATS Room Pressure Monitors are in operation worldwide, some for as long as 14 years, and are still providing accurate monitoring of negative and positive isolation rooms for the safety and security of health care facilities and their staffs. It was an accurate decision then and the right decision now.

|

|

Isolation Room Equipment/Room Pressure Monitors/Negative Room Pressure and Positive Room Pressure/Pressure Sensor

The CDC Guidelines require that Isolation rooms occupied by TB patients have differential pressure monitored daily by a differential pressure measuring device. The Biological Controls’ ACCUSTAT is a room pressure monitoring device that measures differential pressure between a controlled space and a referenced space. Pressure measurement for a variable volume air supply and exhaust systems is critical for the conservation of energy and the air purification system, as well.

US Center for Disease Control over a decade ago has required hospitals and health care facilities to house patients with infections which potentially could spread through the air in negative pressure rooms. Hospitals and all other health related organizations require positive pressure for surgical suites and areas with immune-compromised patients to limit the chances of airborne infection spreading through the facility. Biological Controls ACCUSTAT Room Pressure Monitor accurately measures the actual room pressure differential, verifying the proper operation of your HVAC or your air purification system to help you maintain patient safety.

CDC Guidelines were established and requirements so that a successful project to develop a new Isolation Room in any institution should include early involvement of the nursing staff who will manage the room, the Infection Control Department, and the maintenance staff as well as the architect who will design the space. In many cases hospital and health care facilities convert and existing room into an isolation room, within the facilities as the need arises. Thus creating the need for a Room Pressure Monitor for negative and positive pressure, Hospital Isolation Room Equipment.

Important Engineering Features for Negative Pressure Rooms and Positive Pressure Rooms:

The room airflow should be a minimum of 12 air changes per hour. The CDC Guidelines do not specify if the airflow or exhaust airflow should equal 12 air changes per hour, but making the supply airflow equal to 12 air changes per hour is the most conservative approach. They do specify that the exhaust airflow volume should exceed the supply airflow volume by 10% or 50 CFM, whichever is greater, to maintain a negative pressure within the room with respect to surrounding areas. The negative pressure will cause an inward flow of air into the Isolation Room when the doors are opened, preventing the migration of airborne pathogens to the surrounding areas. The effectiveness of the 12 air changes standard has not been proven with regard to minimizing TB bacteria in a room; however, actual experiments have proven that increasing airflow rates in hospitals does show a reduction in total bacteria counts in the air.

The ACCUSTAT pressure sensor, sensing through pressure the static differential between the two referenced spaces. If variable volume is used, it is imperative that accurate, reliable controls be used to sense the pressure differential between the patient room and the surroundings and adjust the air purification/ exhaust system to maintain the desired pressure differential. The CDC Guidelines specify a minimum pressure differential of 0.001 inches w.g. (water gauge). Which can be accomplished utilizing the ACCUSTAT Room Pressure Monitor.

ACCUSTAT Room Pressure Sensor is CDC compliant in providing a visible and/or audible alarm when low air pressure is sensed, while incorporating a time delay, to allow persons to enter or leave the room without activating the signal. If an anteroom is provided with the Isolation Room, the guidelines require that the Isolation Room be maintained at negative pressure with respect to the anteroom. The pressure relationship between the anteroom and the corridor is that the anteroom should be slightly negative to the corridor and is measured utilizing a probe tube.

The Isolation Room should be well sealed from the surroundings to help maintain the pressure differentials. Penetrations through walls must be sealed and drywall ceiling should be used or drop ceiling tiles that are impervious to air. Swinging doors are easier than sliding doors.

Aspergillus Control (MOLD)

While the Joint Commission on Accreditation of Healthcare Organizations (JCAHO) has long required the operation and maintenance of building systems to address infection control issues, an increased national focus on patient safety has recently prompted it to add more specific requirements to the Environment of Care, EC.1.9

Specifically, beginning January 1, 2001, the utility systems management program must “reduce the potential for organized-acquired illness,” and maintain “appropriate pressure relationship, air exchange rates, and filtration efficiencies for ventilation systems serving areas specifically designed to control airborne contaminants,” such as dust and biological agents. JCAHO will focus additional attention on precautions taken to protect high risk patients. Subsequently more health care facilities and hospitals will find greater need to create negative air pressure Isolation Rooms and the need to monitor room pressure. Biological Controls Room Pressure Monitors Sensor Isolation Room Equipment comes with a complete two year warranty and customer support.

Despite the risk analysis, however, always ensure that proper air pressure relationships in an area with high risk patients. Develop protocols to ensure that proper ventilation rates are maintained annually.

Limiting the spread of disease through a health care facility, patients suspected of having diseases will spread through the air and must be placed in negative pressure rooms, airborne infection Isolation Rooms. Similarly, immune-compromised patients at risk of contracting diseases should stay in positive pressure, protective environment rooms. Biological Controls' room pressure monitors continuously controls room pressure, by monitoring differential to comply with standards from the CDC Centers for Disease Control and AIA American Institute of Architects.

Features and Benefits of ACCUSTAT Room Pressure Monitor for Negative & Positive Pressure Rooms

- Creates a complaint, controlled and safe environment

- Highly sensitive pressure transducer eliminating the varying inconsistencies of “airflow” monitors

- CDC Complaint providing visual, audible and alarm signals

- Large lighted digital readout identifies subfractional pressure changes within .001” WG

- Continuously measurements monitoring of actual room pressure differential

- Temperature compensation for consistent performance within specified temperature ranges

- Three models Stationary, Business Management System and Portable (multiple locations)

- Portable Unit preferred by facilities using mobile equipment (Click here for MICROCON® The Mobile Hospital Air Purification System) room to room set up temporary or short term negative or positive pressure environments. (Click here for Isoport our Portable Isolation Room Enclosure)

- Remote Monitoring up to six rooms

- Pressure sensor sensing through pressure the static differential between the two referenced spaces

Room Pressure Monitors for Clean Rooms

Most significant concern is contamination control and is of utmost importance in a clean room. High air change rates and laminar airflow are two of the methods used to keep impurities away from crucial yield. Measures can become ineffective if the clean room pressure differential should go negative, sucking in contaminants. ACCUSTAT clean room pressure monitors sensor constantly measure the room pressure differential, signaling if the space goes negative so appropriate action can be taken.

|

|

|